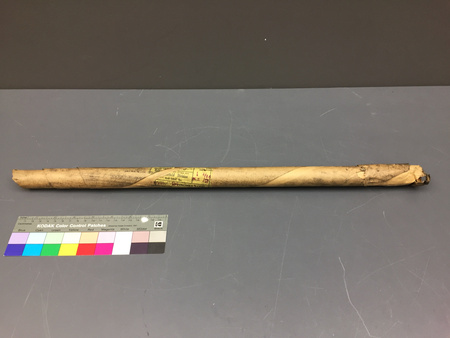

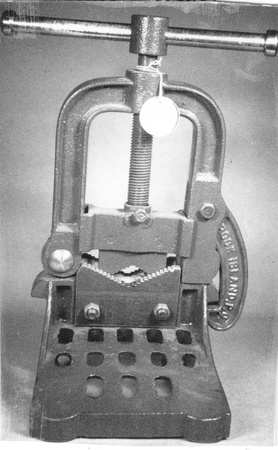

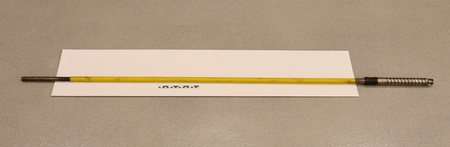

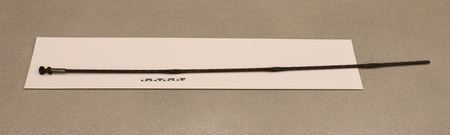

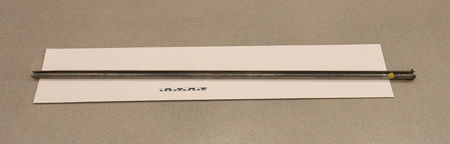

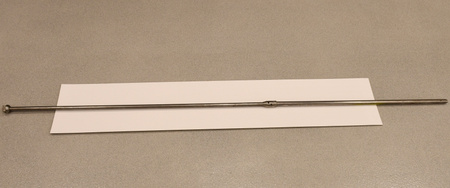

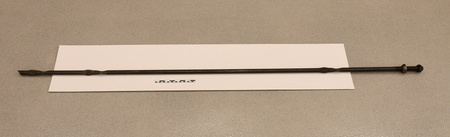

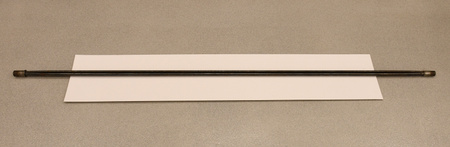

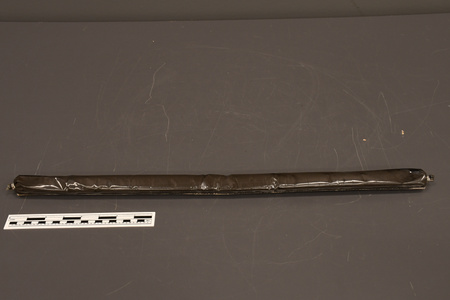

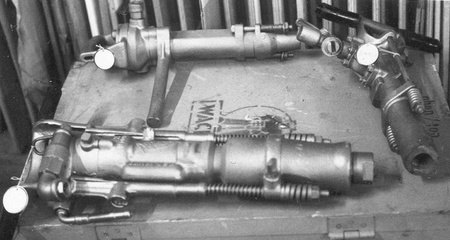

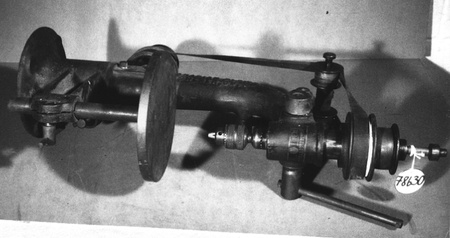

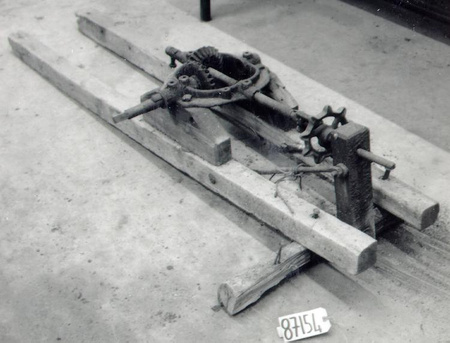

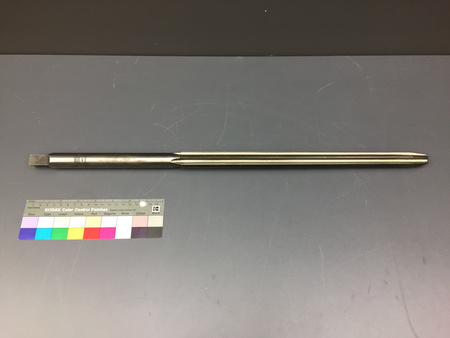

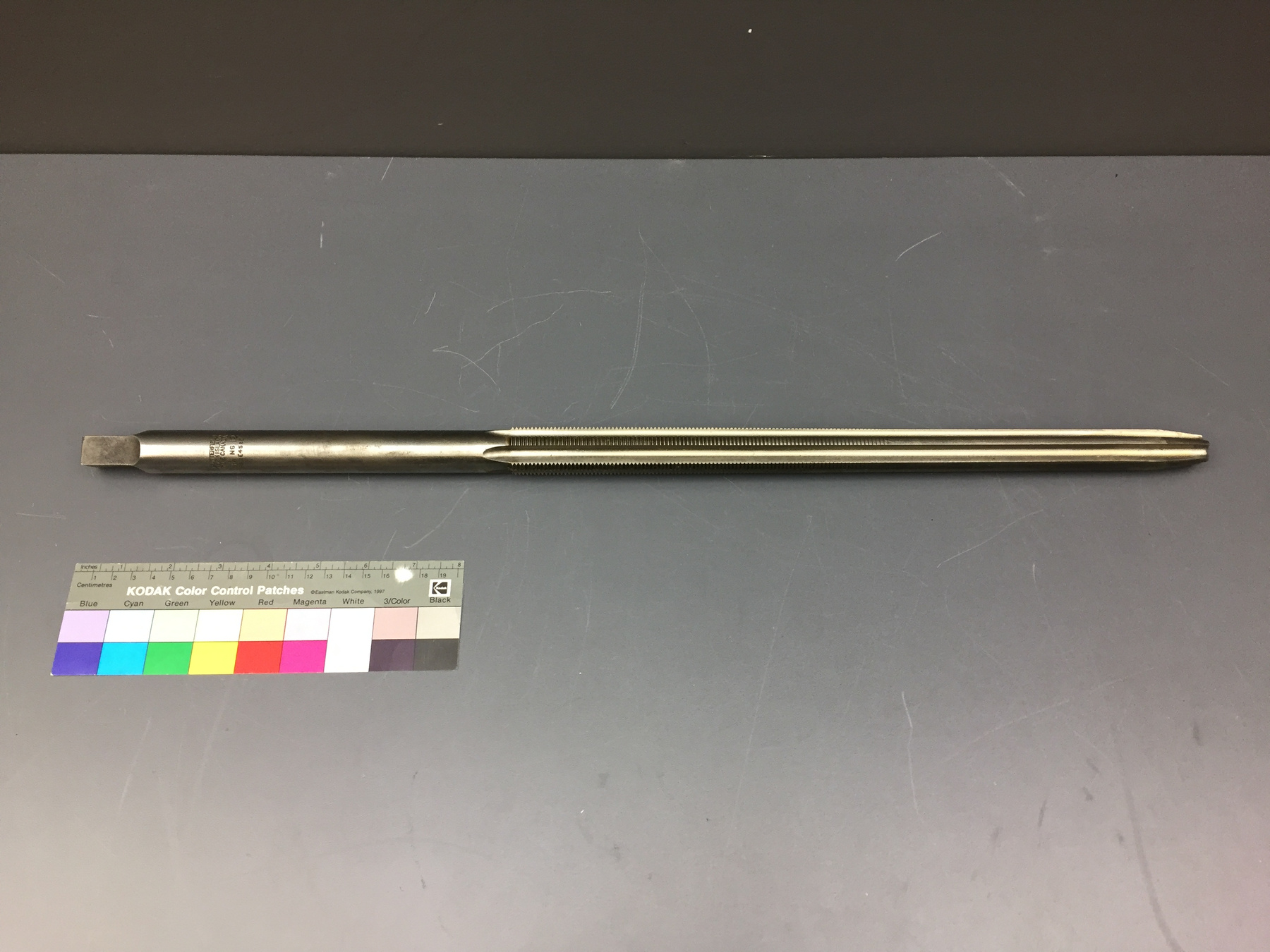

Tap, stay bolt

Use this image

Can I reuse this image without permission? Yes

Object images on the Ingenium Collection’s portal have the following Creative Commons license:

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUTE THIS IMAGE

Ingenium,

2016.0181.001

Permalink:

Ingenium is releasing this image under the Creative Commons licensing framework, and encourages downloading and reuse for non-commercial purposes. Please acknowledge Ingenium and cite the artifact number.

DOWNLOAD IMAGEPURCHASE THIS IMAGE

This image is free for non-commercial use.

For commercial use, please consult our Reproduction Fees and contact us to purchase the image.

- OBJECT TYPE

- N/A

- DATE

- 1960

- ARTIFACT NUMBER

- 2016.0181.001

- MANUFACTURER

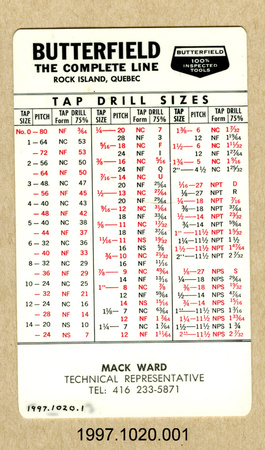

- Union Twist Drill Co.

- MODEL

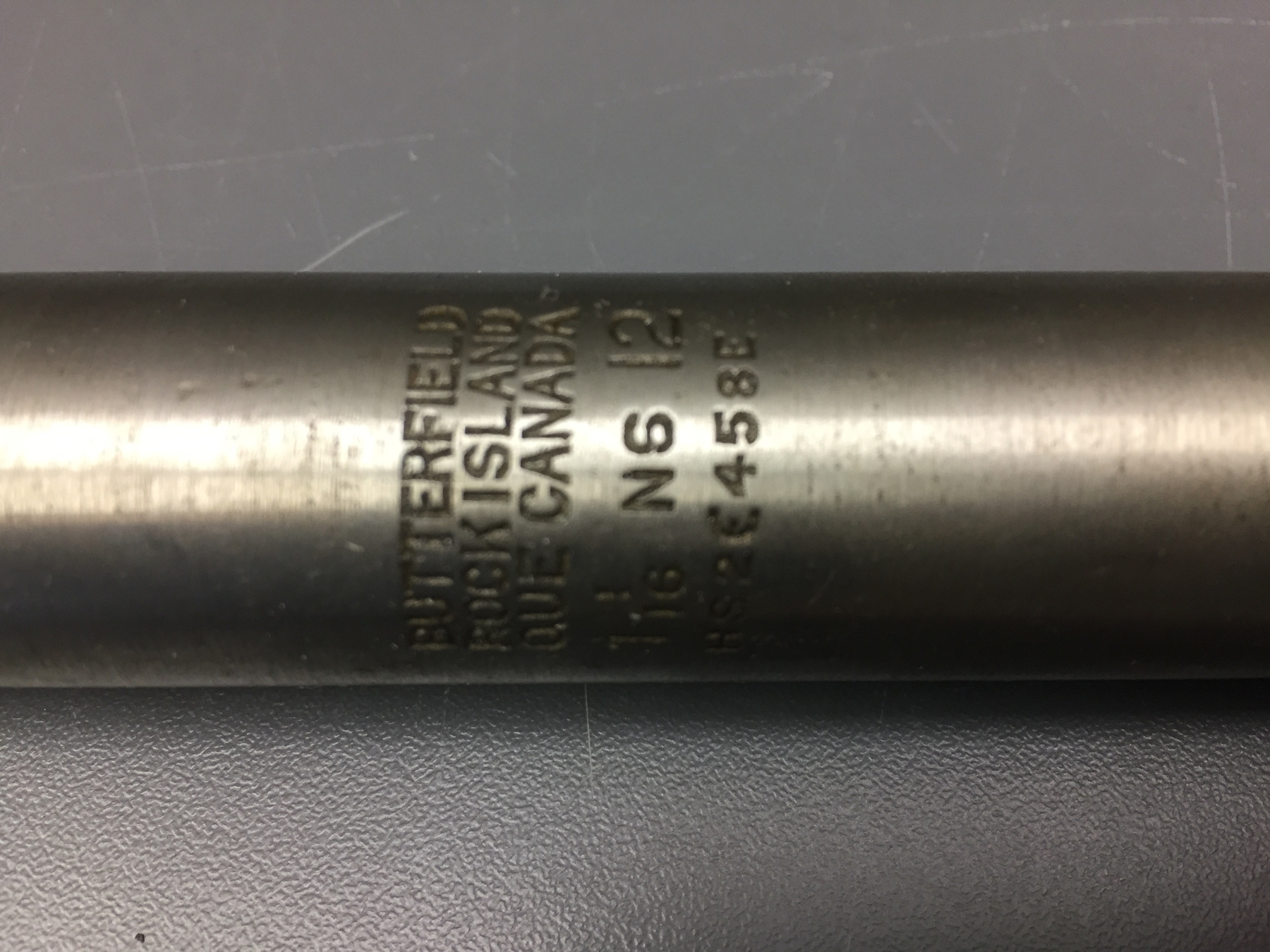

- 1 1/16 N.S. 12

- LOCATION

- Rock Island, Quebec, Canada

More Information

General Information

- Serial #

- HS2E458E

- Part Number

- 1

- Total Parts

- 2

- AKA

- N/A

- Patents

- N/A

- General Description

- Ferrous metal

Dimensions

Note: These reflect the general size for storage and are not necessarily representative of the object's true dimensions.

- Length

- 61.2 cm

- Width

- N/A

- Height

- N/A

- Thickness

- N/A

- Weight

- N/A

- Diameter

- 2.7 cm

- Volume

- N/A

Lexicon

- Group

- Railway Transportation

- Category

- Operations

- Sub-Category

- N/A

Manufacturer

- AKA

- Union

- Country

- Canada

- State/Province

- Quebec

- City

- Rock Island

Context

- Country

- Unknown

- State/Province

- Unknown

- Period

- New, unused

- Canada

-

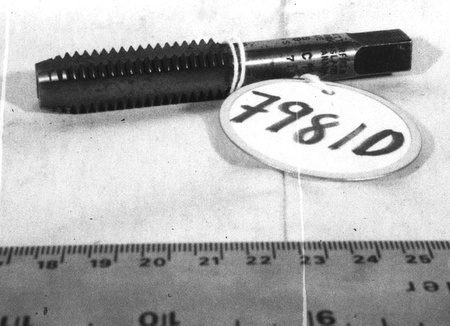

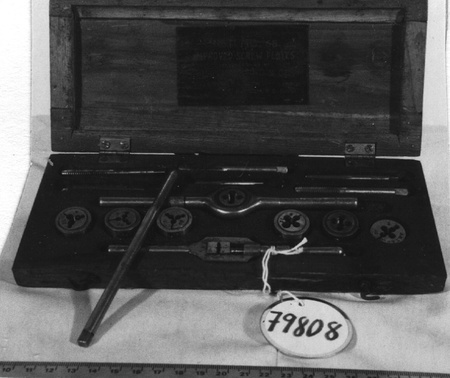

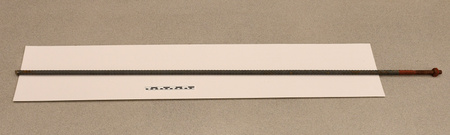

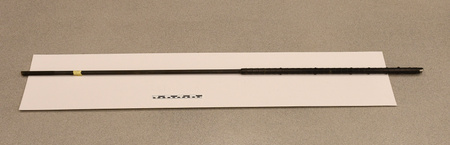

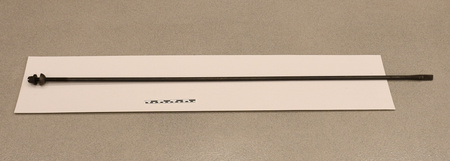

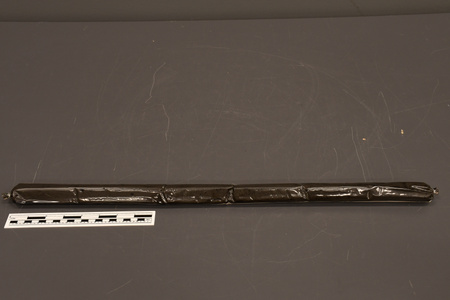

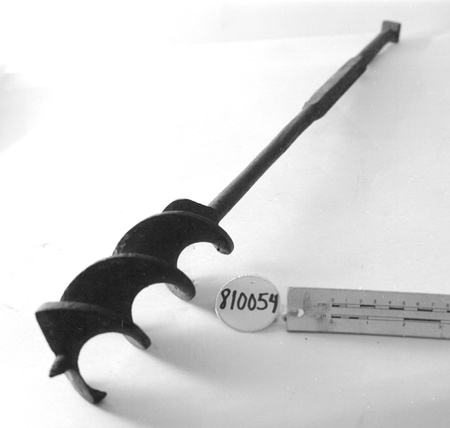

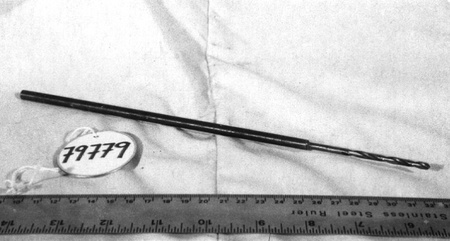

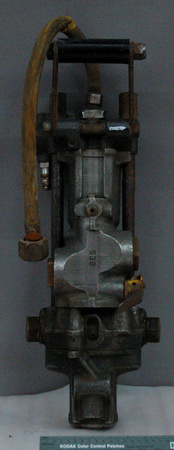

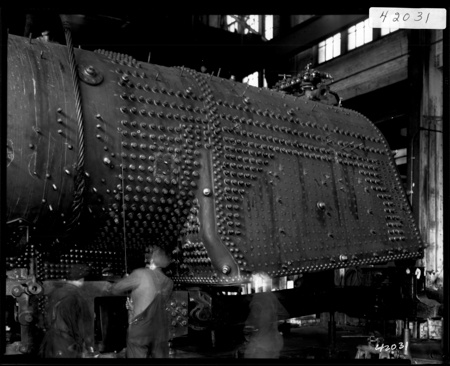

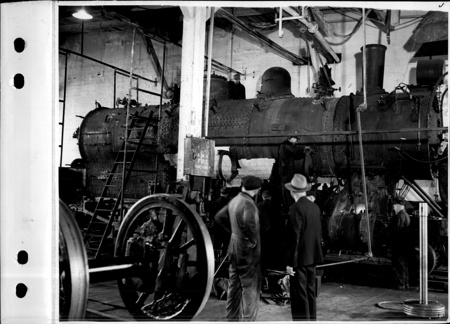

Taken from acquisition worksheet "Until the 1950s, Canadian railways relied on a fleet of over 4000 steam locomotives to move goods and people across Canada. At the heart of each of these vehicles was the boiler where steam was produced and collected before being deployed to cylinders and pistons. Boilers are subjected to a great deal of wear and tear in the course of regular operation and so were built as sturdily as possible and then regularly inspected, repaired and re-built. Railways employed a large number of boilermakers (and related tradesmen) to do this work. This stay bolt tap is an example of one of the many tools used by boilermakers to repair and re-build locomotive boilers. This tap is part of a collection of tools that CSTMC curatorial and restoration staff acquired on a trip to Glace Bay in the early 1980s. Their goal was to obtain any and all tools that they thought would be useful in maintaining the Museum’s working steam locomotives. Butterfield & Company of Rock Island, Quebec, began making metal working tools in the late 19th century. By the 1920s, the company had built a large factory that straddled the Quebec-Vermont border and produced the latest in hardened steel tools including taps and dies. At its peak, the company employed about 800 people. Purchased by Litton Industries in the late 1960s, Butterfield became a division of the Union Twist Drill Company. Litton closed the Canadian side of the business in 1982 and eventually moved all its operations to North Carolina.". "The boiler is power source for a steam-powered engine. It is a metal (iron or steel) pressure vessel that contains boiling water and its natural by-product, steam. Contained within a closed space, the steam reaches pressures of over 200 pounds per square inch (psi). This exerts a huge amount of force on the sheet metal walls of the boiler which, depending on the thickness of the plates, would eventually bulge or buckle under the pressure. To prevent this from happening, boilermakers installed stay bolts to reinforce the boiler walls. Depending on the design of the boiler and its pressure rating, the boilermaker and his team had to place stay bolts every 5 to 10 inches across the entire surface of the boiler. But first they had to drill holes in both the inside and outside walls of the boiler and thread them to take the bolts. To do the threading, they used stay bolt taps usually attached to a pneumatic motor. The tap had to be long enough to create precise and continuous threads in both the inside and outside metal sheets of the boiler. This way the stay bolt would fit perfectly in both openings and could be tightly bolted in place." - Function

-

Used to thread a hole for a stay-bolt. - Technical

-

Taken from acquisition worksheet "Steam locomotive boilers had to be maintained, re-built and replaced on a regular basis. To carry out this work, the railway companies employed a large number of boilermakers, fitters, apprentices and labourers. Tapping the boiler was one of their critical functions and stay bolt tapping accounted for the greatest amount of their tapping work. In the 20th century, most locomotive shops would have been equipped with air motors that workers would have used to power many of tools including the stay bolt taps.". - Area Notes

-

Unknown

Details

- Markings

- Incised print reads "BUTTERFIELD/ ROCK ISLAND/ QUE CANADA/ 1 '16 N6 12/ HS2E458E".

- Missing

- Appears complete.

- Finish

- Machined ferrous metal with incised print.

- Decoration

- N/A

CITE THIS OBJECT

If you choose to share our information about this collection object, please cite:

Union Twist Drill Co., Tap, stay bolt, circa 1960, Artifact no. 2016.0181, Ingenium – Canada’s Museums of Science and Innovation, http://collection.ingenium.ca/en/id/2016.0181.001/

FEEDBACK

Submit a question or comment about this artifact.

More Like This